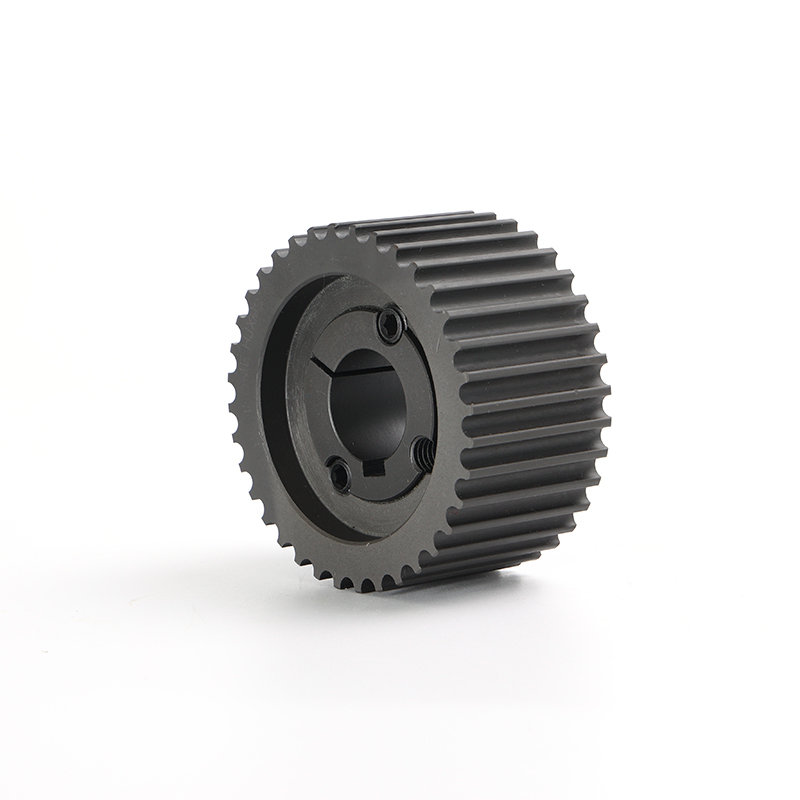

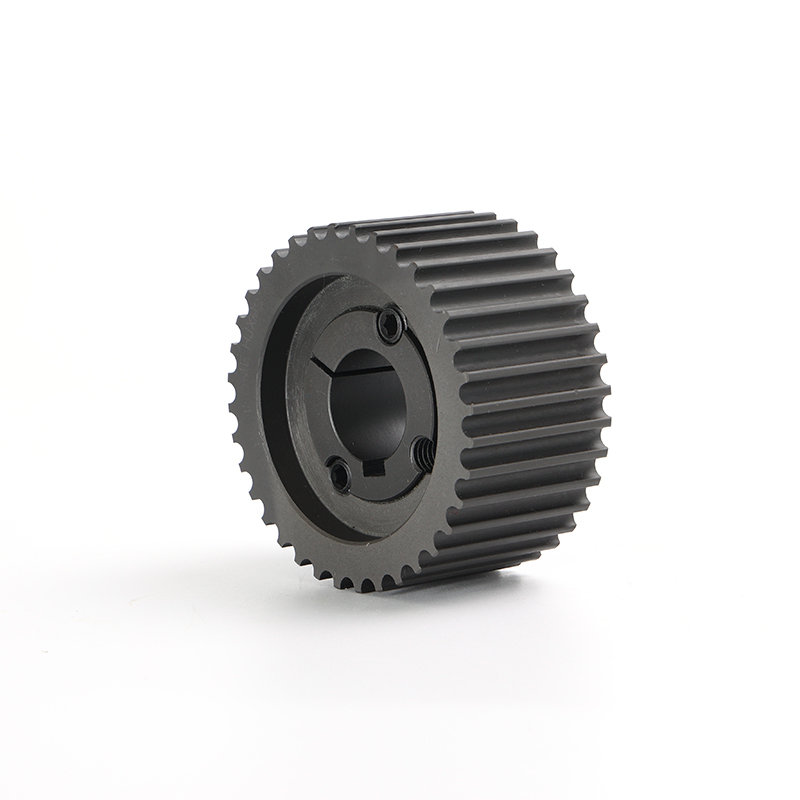

The discussion of modern Synchronized pulley manufacturing technology is a topic closely related to high-performance materials and precision processing technology. With the continuous advancement of industrial technology, the requirements for Synchronized pulley are becoming higher and higher. Therefore, the use of high-performance materials combined with precision processing technology has become an important trend in modern Synchronized pulley manufacturing.

First, high-performance materials play an important role in modern synchronized pulley manufacturing. For example, lightweight and high-strength materials such as carbon fiber reinforced polymer (CFRP) and aluminum alloy are widely used in the manufacture of Synchronized pulley. These materials have excellent wear resistance, tensile strength and corrosion resistance, and can effectively improve Synchronized pulley. service life and reliability, while reducing the quality of the entire transmission system and improving the performance and fuel efficiency of automobiles and other mechanical equipment.

Secondly, precision machining technology is crucial to the manufacturing of Synchronized pulley. Modern precision machining technologies include CNC machining, laser cutting, EDM, etc., which can achieve high-precision and high-efficiency processing during the manufacturing process of Synchronized pulley, ensuring that the dimensional accuracy and surface quality of Synchronized pulley meet the design requirements. The application of precision machining technology can effectively improve the transmission accuracy of Synchronized pulley, reduce vibration noise, and increase its working stability and reliability.

At the same time, modern Synchronized pulley manufacturing technology also needs to fully consider the matching of materials and processing technology. For example, corresponding precision machining processes are adopted according to different material properties to ensure that unnecessary wear and fatigue does not occur during high-speed operation, thereby extending the service life of the Synchronized pulley and improving the reliability and safety of the overall transmission system.

In general, the discussion of modern Synchronized pulley manufacturing technology needs to combine high-performance materials and precision processing technology to meet the demand for Synchronized pulley's high strength, lightweight, and high precision. Through continuous material research and development and processing technology improvement, it is believed that modern Synchronized pulley manufacturing technology will continue to achieve new breakthroughs and provide more reliable technical support for the development of automobiles, mechanical equipment and other fields.